REVIEW OF A BROKEN WATCH

This 1981 watch sits on my work bench all the time. The only functions that work correctly on it are the chronograph and the countdown timer.

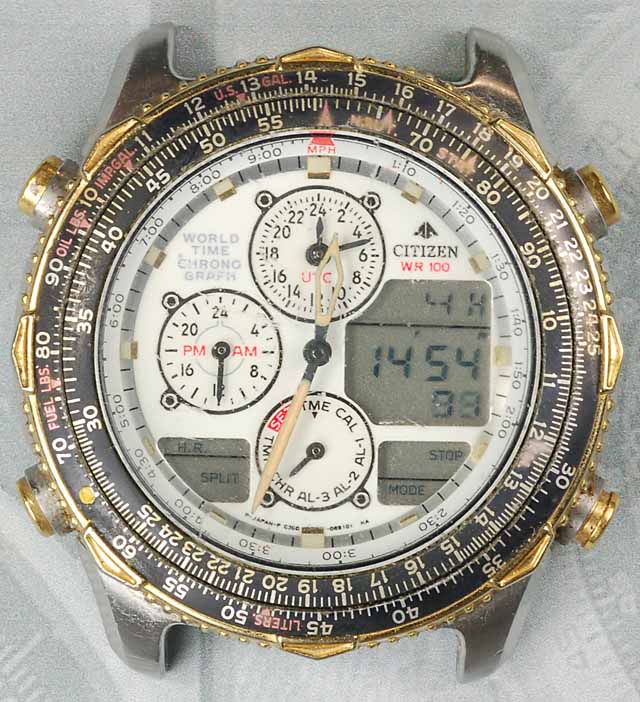

It was a quite a fancy watch in it's day. 60g of heft, 20mm lugs, 13mm thick and a 41mm slide-rule bezel. It sports gold trim on the bezel, gold pushers, a white dial and the well-known Citizen C300 movement. This movement has a common fault: everything seems fine until you pull out the bottom right-hand pusher to reset the watch after a battery change or to change between regular and summer time. Nothing happens. The contact inside the movement has failed. However, the chronograph function is unaffected (nothing to set) and is perfect for watch regulating with it's 24 hr capacity, 1/100 sec resolution and especially the "split time" feature. The split time feature lets you check the regulation after a few minutes of running without stopping the chrono - this gives you an early check on the goodness of the regulation. The slide rule bezel still works smoothly and I do use it to calculate the daily rate of a watch.

Here's how: assume that the watch had run for 60 minutes and the split time measurement said that the watch was off by 0.85 sec. Realistically, this means somewhere between say 0.8 and 0.9 secs (accounting for human reaction time). Set 1440 (the number of minutes in a day) on the outer scale next to 60 (minutes elapsed for this example) on the inner, as in the above picture.

Now look for 0.8 to 0.9 (secs error) on the inner scale. On the outer scale, we see that this corresponds to between about 19 and 22 secs per day error. It's not strictly necessary to wait a whole hour to get an accurate result. You can get a feel for how well a watch is keeping time in as little as 5 or 10 minutes and make some initial adjustments to the regulator. The final test is still to wear the watch for one whole day, of course.